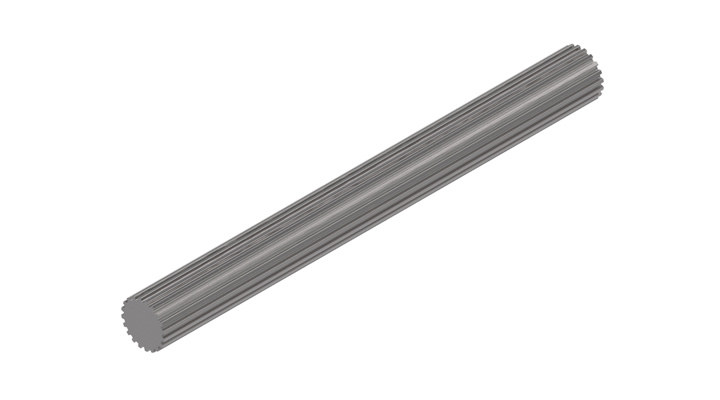

Product Description

product description

| Material | Stainless Steel, Brass, Aluminum, Steel, Carbon Steel, Copper & etc |

| Precision Processing | Drilling, Milling, CNC turning, Grinding, Wire cutting, EDM & etc |

| Dimension | As per customers’ request |

| Surface treatment | Anodize; polishing; zinc/nickel/chrome/gold plating, sand blasting, Phosphate coating & etc |

| Tolerance | ±0.01mm ~± 0.05mm/can also be customized |

| Part Color | Silver, Red, Blue, Gold, Oliver, Black, White & etc |

| Quality control | 100% inspection before shipment |

| Samples | Acceptable |

| Production output | 100.000 pieces/ month |

| Productin range | from 1-2000mm with tolerance ±0.01mm |

| Experience | 7 years of professional OEM service |

| Ability | To develop hundreds of new parts annually. |

| Packaging | carton box, wooden case/according to the clients |

| delivery time | 45 days regularly /Based on the quantity of order |

| Shipping | By sea, By air, By DHL,UPS ,TNT& etc. |

| Term of Payment | T/T. L/C or Customer’s request |

Product Image

Company Profile

1. We are cnc machining/turning/Stamping/Casting supplier in HangZhou .

2. We provide goods in high quality and competitive price and professional service .

3. “Excellence, Responsibility, Science”is the pursuit of our company.

4. Material:brass, stainless steel, aluminum, plastic ,etc.

HangZhou CHINAMFG Machinery Technology Co., Ltd

HangZhou CHINAMFG Machinery Technology Co., Ltd is a subsidiary company of HangZhou Kehong Machinery Co.,Ltd. We specialize in manufacturing: precision CNC machining parts, hardware components, standard and non- standard parts, general machinery and photovoltaic components ect. We provide the complete machining-service: turning, milling,drilling,grinding,boring, bending,stamping, welding,surface treatment, laser machining, wire EDM, and other CNC machining fabricating according to samples or drawings from customers.

We have the main equipments over 20 units: Vertical machining centers-6 sets, Horizontal machining center-1 set ,CNC lathes-4 sets, ,plain milling machine ,engine Lathe, Surface grinder and others.our testing equipments: Switzerland electronic digital display measuring grohe, Rockwell apparatus ,micrometer,vernier caliper, etc.

” Excellence, Responsibility, Science ” is the pursuit of our company. We have the united team with scientific technology and responsible attitude. It is the key base for making the excellent quality & service for you and achieving the win-win business.

| Equipment List | ||||

| equipment name | processing range | spindle taper | number | note |

| Horizontal machining center | 1100×750×650 | ISO50 | 1 | four-axis |

| Vertical machining center | 1300×650×920 | ISO50 | 2 | four-axis |

| Vertical machining center | 1100×600×750 | ISO50 | 1 | four-axis |

| Vertical machining center | 1070×560×750 | ISO40 | 1 | four-axis |

| Vertical machining center | 800×450×550 | ISO40 | 2 | |

| cnc lathe 6150 | Ø500×850 | 3 | ||

| cnc lathe CJK 0571 | Ø220×310 | 1 | ||

| engine 6150 | Ø500×1500 | 2 | ||

| engine 6140 | Ø400×100 | 2 | ||

| surface grinder 7130 | 1000×300 | 1 | ||

| vertical milling machine | 700×320×450 | 2 | ||

| horizontal milling machine | 600×320×450 | 1 | ||

| Drilling machine with jointed arm | Ø40×1100 | 1 | ||

| bench drill | φ20 | 3 | ||

| tapper | M16 | 1 | ||

| vernier caliper | 0-1000mm | 28 | ||

| depthometer | 0-300mm | 6 | ||

| tongue | 0-500mm | 3 | ||

| micrometer | 0-255mm | 25 | ||

| electronic digital display measuring grohe | 400MM | 1 | Switzerland | |

| Rockwell apparatus | 1 | |||

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Condition: | New |

|---|---|

| Certification: | CE, ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Samples: |

US$ 4.8/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can spline shafts be customized for specific machinery and equipment?

Yes, spline shafts can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Size and Length:

Spline shafts can be customized in terms of size and length to fit the dimensions of the machinery or equipment. Manufacturers can design spline shafts with the appropriate diameter, overall length, and spline length to ensure a proper fit within the system.

2. Spline Profile:

The spline profile can be customized based on the specific application. Different spline profiles, such as involute, serrated, or helical, can be used to optimize torque transmission, load distribution, and engagement characteristics based on the requirements of the machinery or equipment.

3. Number of Splines:

The number of splines on the shaft can be customized to match the mating component. The number of splines determines the engagement area and affects the torque-carrying capacity of the spline shaft. By adjusting the number of splines, manufacturers can tailor the spline shaft to the specific torque and load requirements of the machinery or equipment.

4. Material Selection:

The choice of material for spline shafts can be customized based on the operating conditions and environmental factors of the machinery or equipment. Different materials, such as alloy steels or stainless steels, can be selected to provide the necessary strength, durability, corrosion resistance, or other specific properties required for the application.

5. Surface Treatment:

The surface of spline shafts can be customized with various treatments to enhance their performance. Surface treatments like heat treatment, coating, or plating can be applied to improve hardness, wear resistance, or corrosion resistance based on the specific requirements of the machinery or equipment.

6. Tolerances and Fit:

Tolerances and fit between the spline shaft and mating components can be customized to achieve the desired clearance or interference fit. This ensures proper engagement, smooth operation, and optimal performance of the machinery or equipment.

7. Special Features:

In certain cases, spline shafts can be customized with additional features to meet specific needs. This may include the incorporation of keyways, threads, or other specialized features required for the machinery or equipment.

Manufacturers and engineers work closely with the machinery or equipment designers to understand the specific requirements and tailor the spline shafts accordingly. By considering factors such as size, spline profile, number of splines, material selection, surface treatment, tolerances, fit, and any special features, customized spline shafts can be developed to ensure optimal performance and compatibility with the machinery or equipment.

It is important to consult with experienced spline shaft manufacturers or engineering professionals to determine the most suitable customization options for a particular machinery or equipment application.

Can spline shafts be used in automotive applications, and if so, how?

Yes, spline shafts are extensively used in automotive applications due to their ability to transmit torque and provide reliable power transmission. Here’s how spline shafts are used in automotive applications:

Spline shafts play a crucial role in various automotive systems and components, including:

- Drivetrain: Spline shafts are an integral part of the drivetrain system in vehicles. They transmit torque from the engine to the wheels, allowing the vehicle to move. Spline shafts are present in components such as the transmission, differential, and axle shafts. In manual transmissions, the spline shaft connects the transmission input shaft to the clutch disc, enabling power transfer from the engine. In automatic transmissions, spline shafts are used in the torque converter and the output shaft.

- Steering System: Spline shafts are employed in the steering system to transmit torque from the steering wheel to the steering rack or gearbox. They provide a direct connection between the driver’s input and the movement of the wheels, allowing for steering control.

- Power Take-Off (PTO) Systems: Some vehicles, particularly commercial trucks and agricultural machinery, utilize PTO systems. Spline shafts are used in PTOs to transfer power from the vehicle’s engine to auxiliary equipment, such as hydraulic pumps, generators, or agricultural implements.

- Transfer Cases: In four-wheel-drive (4WD) or all-wheel-drive (AWD) vehicles, transfer cases are used to distribute power to the front and rear axles. Spline shafts are utilized in the transfer case to transfer torque between the transmission and the front and rear drive shafts.

- Propeller Shafts: Spline shafts are present in propeller shafts, which transmit torque from the transmission or transfer case to the rear axle in rear-wheel-drive vehicles. They accommodate the relative movement between the transmission and the axle due to suspension travel.

In automotive applications, spline shafts are designed to withstand high torque loads, provide precise torque transmission, and accommodate misalignments and fluctuations in operating conditions. They are typically made from high-strength steel or alloy materials to ensure durability and resistance to wear. Proper lubrication is essential to minimize friction and ensure smooth operation.

The use of spline shafts in automotive applications allows for efficient power transmission, precise control, and reliable performance, contributing to the overall functionality and drivability of vehicles.

What are the key components and design features of a spline shaft?

A spline shaft consists of several key components and incorporates specific design features to ensure its functionality and performance. Here’s a detailed explanation:

1. Shaft Body:

The main component of a spline shaft is the shaft body, which provides the structural integrity and serves as the base for the spline features. The shaft body is typically cylindrical in shape and made from materials such as steel, stainless steel, or other alloyed metals. The material selection depends on factors like the application requirements, torque loads, and environmental conditions.

2. Splines:

The splines are the key design feature of a spline shaft. They are ridges or teeth that are machined onto the surface of the shaft. The splines create the interlocking mechanism with mating components, allowing for torque transmission and relative movement. The number, size, and shape of the splines can vary depending on the application requirements and design specifications.

3. Spline Profile:

The spline profile refers to the specific shape or geometry of the splines. Common types of spline profiles include involute, straight-sided, and serrated. The spline profile is chosen based on factors such as the torque transmission requirements, load distribution, and the desired engagement characteristics with mating components. The spline profile ensures optimal contact and torque transfer between the spline shaft and the mating component.

4. Spline Fit:

The spline fit refers to the dimensional relationship between the spline shaft and the mating component. It determines the clearance or interference between the splines, ensuring proper engagement and transmission of torque. The spline fit can be categorized into different classes, such as clearance fit, transition fit, or interference fit, based on the desired level of clearance or interference.

5. Surface Finish:

The surface finish of the spline shaft is crucial for its performance. The splines and the shaft body should have a smooth and consistent surface finish to minimize friction, wear, and the risk of stress concentrations. The surface finish can be achieved through machining, grinding, or other surface treatment methods to meet the required specifications.

6. Lubrication:

To ensure smooth operation and reduce wear, lubrication is often employed for spline shafts. Lubricants with appropriate viscosity and lubricating properties are applied to the spline interface to minimize friction, dissipate heat, and prevent premature wear or damage to the splines and mating components. Lubrication also helps in maintaining the functionality and prolonging the service life of the spline shaft.

7. Machining Tolerances:

Precision machining is critical for spline shafts to achieve the required dimensional accuracy and ensure proper engagement with mating components. Tight machining tolerances are maintained during the manufacturing process to ensure the spline profile, dimensions, and surface finish meet the specified design requirements. This ensures the interchangeability and compatibility of spline shafts in various applications.

In summary, the key components and design features of a spline shaft include the shaft body, splines, spline profile, spline fit, surface finish, lubrication, and machining tolerances. These elements work together to enable torque transmission, relative movement, and load distribution while ensuring the functionality, durability, and performance of the spline shaft.

editor by CX 2023-09-19